Industrial effluent wastewater treatment scope of work

MAT-KULING provides the design, supply equipment, install and commission of industrial effluent treatment plant equipment allowing the industries to directly discharge their treated wastewater to a receiving water body, or indirectly to a municipal wastewater treatment plant or re-use the water in-plant.

MAT-KULING can adopt its tailored products based on the local conditions and can also provide compact wastewater treatment and re-use solutions for limited foot prints.

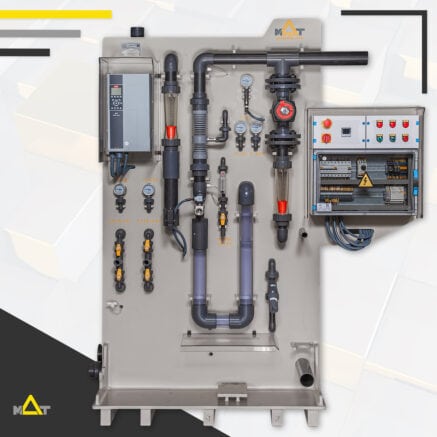

From small systems with 0.1 m³/day up to large systems with dozens of thousands m³/day, we provide tailored pre-built Skid sets that are easy to install, operate and maintain.

MAT-KULING arranges treatment methods and equipment according to the required performance while optimizing quality, price, operating costs and environmental impacts owed to its multinational process experts and product managers experienced on industrial wastewater treatment and re-use applications in a variety of industries.

Industrial effluent wastewater vs municipal wastewater treatment

Industrial wastewater strongly differs from municipal wastewater since there are different types of pollutants at different concentrations. MAT-KULING provides tailor-made industrial wastewater treatment and recovery equipment for your specific requirements in order to create solutions that fulfill the latest regulations in the most cost-effective way.

Undesirable Industrial Wastewater Characteristics

MAT-KULING considers industry characteristics, latest regulations, treatment alternatives while proposing solutions or equipment to overcome specific undesirable waste water characteristics.

- Industry production specific constituents

- Soluble organics: depletion of dissolved oxygen

- Suspended solids: progressive decomposition resulting in oxygen depletion and noxious gases

- Priority organic pollutants: cause taste and odor and in some cases are carcinogenic

- Heavy metals, cyanide, and toxic organics

- Color and turbidity

- Nitrogen and phosphorus: enhance eutrophication and stimulate undesirable algae growth

- Refractory & Toxic Substances

- Oil and floating material

- Volatile materials such as hydrogen sulfide

Effluent & Wastewater Treatment Industrial Equipment

Industrial Wastewater Treatment Services

Primary treatment

Primary treatment prepares waste water for biological treatment and other fine/selective treatment stages.

- Screening

- Equalization

- Neutralization

- Coagulation & Flocculation

- Sedimentation

- Dissolved Air Flotation (DAF)

Secondary Treatment

Secondary Treatment degrades soluble compounds aerobically where they may be pre-treated anaerobically according to the industry.

- Activated Sludge Tanks (AST)

- Moving Bed Bio Film Reactors (MBBR)

- Membrane Bio Reactors (MBR)

- Trickling Units (TU)

- Rotating Biological Contactors (RBC)

- Up flow Anaerobic Sludge Blanket Reactors (UASB)

- Expended Granular Sludge Bed Reactors (EGSB)

- Sequencing Batch Reactors (SBR)

Tertiary Treatment

Tertiary Treatment removes specific types of residuals/pollutants that are toxic to aquatic life.

- Media Filtration

- Membrane Filtration (MF, UF)

- Adsorption

- Chemical Dis-Infection

- Ozonation

- UV-C Dis-Infection

- Advanced Oxidation (AOP)

In Plant Treatment

In Plant Treatment is located in the industry to remove specific pollutants from a small but concreted stream instead of large but diluted streams for the sake of the process and cost. In-plant treatments retain toxic substances such as heavy metals and pesticides which may inhibit biological treatments in general purpose waste water treatment plants.

- Media Filtration

- Membrane Filtration (UF, NF)

- Reverse Osmosis

- Adsorption

- Chemical Reduction

- Stripping

- Precipitation

- Ion-Exchange

Sludge Handling

Sludge Handling is applied to handle and control sludges produced by biological treatment and solids-liquid separation process.

- Sludge Thickening

- Sludge Stabilization

- Sludge De-Watering

- Sludge Drying

- Sludge Incineration